Allendale Fibertech Corporation is located in Allendale, SC, USA.

Interested parties can reach out to us for special projects.

We offer toll-processing services in weaving and chopping.

CONTRACT WEAVING:

The reason to choose us for contract weaving can be multifold:

- A weaver may operate at capacity and is looking to outsource some of their existing orders. Or they may not have the right size machine, in order to reach a certain minimum width.

- A distributor may look to expand their product offering or to draw from a more local source, in order to reduce cost in logistics.

- An engineer may look into developing a new product, tailored to his particular industry.

- A sales person may have a great idea of a product he/she thinks can be marketed.

We are passionate about our industry and regardless the size of the project, we would be thrilled to help!

The customer can provide technical or physical requirements such as

- temperature resistances,

- strength requirements,

- insulation values,

- thickness, width or length,

- other.

We then design a fabric which meet such requirements. Our experience with the various fibers available, their properties and the way they need to be processed will help to create successful and cost effective results, in a relatively short period of time.

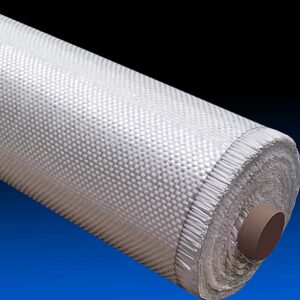

OUR WEAVING CAPABILITIES:

- By modifying our machines, we can weave almost any fiber, be it silk, glass, metal thread and any other fiber prepared for weaving. If a product has been woven somewhere, chances are we can replicate it. The reason is that we use rapier weaving technology. Rapiers are known for their flexibility when it comes to weft fibers.

While rapier weaving machines may not be ideal for all styles in terms of efficiency and productivity, they do produce results and allow us to make samples and the first production runs. - We can weave very narrow panels, from a few inch wide up to 151″ wide panels. On-loom cutter systems allow for weaving multiple panels to the customer’s choice, granted they are of the same weave specification.

- We can weave big rolls (master rolls) which can hold thousands of linear yards or we can weave small rolls, easy to handle & package.

- We can weave from creels and we can weave from loom beams. The choice of either foremostly depends on the warp fiber used for weaving. If the fiber is fine, we will suggest loom beam weaving, dense fibers are often better woven from a creel.

In summery, our weave technology very likely will allow to make samples for you and to run production.

Our knowledge in weaving and the understanding of the desired outcome will help creating shortcuts in the development of a suitable product.It does not have to stop with our machine capabilities! We have an almost all encompassing network of textile experts and companies who would love to help with additional expertise or value added processes.

THE SAMPLE-MAKING PROCESS:

Following an example how this typically works or the process gets started:

- the customer may provide an optional “None-Disclosure Agreement” (NDA), which we sign

- then, the product idea will be discussed and to which extend we may be of help

- then we provide a quotation with terms & conditions

- then the customer accepts the quotation

- then the sample-making begins

- After the sample-making, the customer can decide to outsource the manufacturing through us or can decide to setup his own manufacturing. In the latter, we can help, as well.

CONTRACT CHOPPING

The reason to choose us for contract chopping can be multifold:

- A fiber chopping company may operate at capacity and is looking to outsource some of their existing orders. Or they may not have the right type of chopping technique, to cut certain fibers.

- A distributor may look to expand their product offering or to be able to draw from a more local source, in order to reduce cost in logistics.

- An engineer may look into developing a new product, tailored to his particular industry.

- A sales person may have a great idea of a product he/she thinks can be marketed.

We are passionate about our industry and regardless the size of the project, we would be thrilled to help!

Similar to Contract Weaving, we would ask to provide data to help us determine the optimal choice of fiber or fiber combination.

The advantage of being an independent manufacturer allows us to make use of any fiber available in the market.

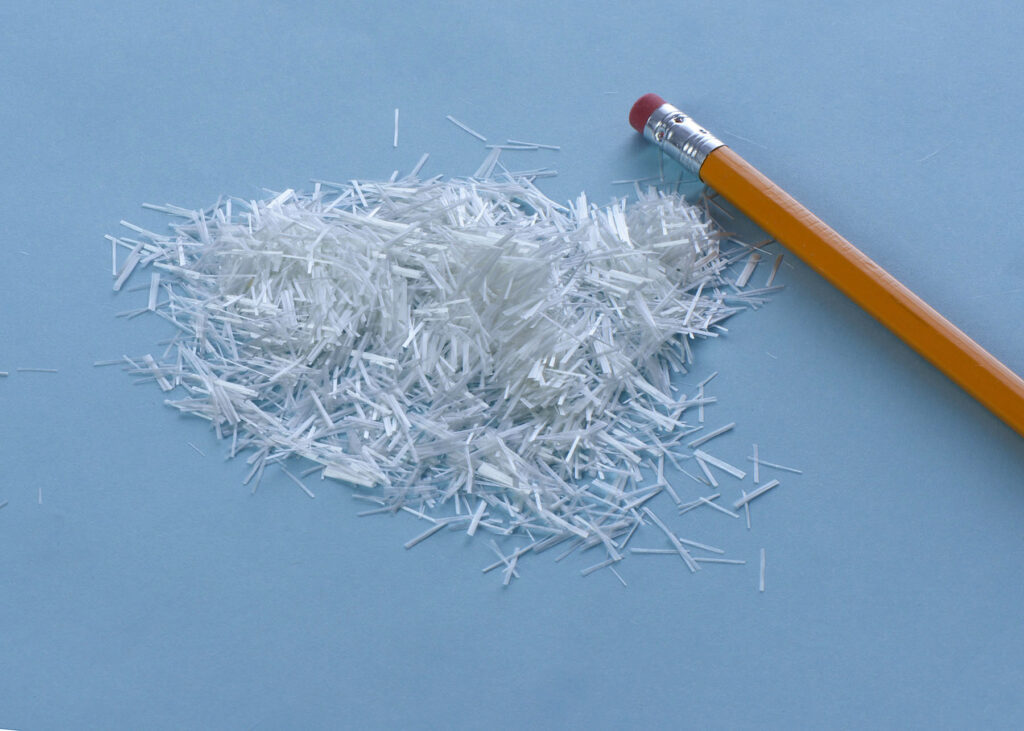

OUR CHOPPING CAPABILITIES:

By modifying our machines, we can chop almost any technical fiber, such as glass, carbon, basalt, etc. Especially fibers with a crystalline structure are suitable for our machines.

Sometimes, blending various fibers may add to optimizing the final product. Our machines thread multiple fibers at the same time and we can run a certain combination, yielding in very exact results.

Following are typical fiber lengths: 1/4″, 1/2″, 3/4″, 1″, others can be discussed.

After the processing, there will be discussions about packaging; here too, we can customize according to customer specification, being it bulk boxes or small bags.

THE SAMPLE-MAKING PROCESS:

Following an example how this typically works or the process gets started:

- The customer may provide an optional “None-Disclosure Agreement” (NDA), which we sign

- then, the product idea will be discussed and to which extend we may be of help

- then we provide a quotation with terms & conditions

- then the customer accepts the quotation

- then the sample-making begins

After the sample-making, the customer can decide to outsource the manufacturing through us or can decide to setup his own manufacturing. In the latter, we can help, as well.

With over 30 years of experience in Technical fibers, and along with it a lot of connections around the globe, we believe we can be a valuable manufacturing partner.

Just reach out to us and we can discuss your ideas.

We are looking forward to working with you !

The Allendale Fibertech – Team

CEO – Rogier Cuylits